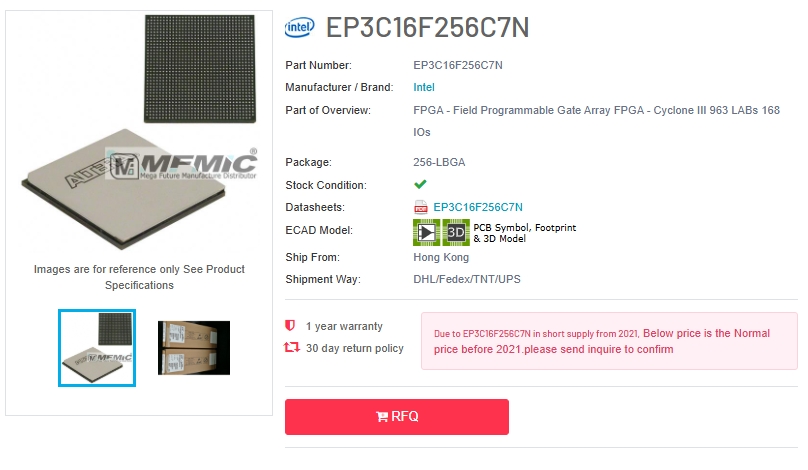

The construction and maintenance cost analysis of semiconductor cleanrooms is an important issue in the semiconductor manufacturing industry. The clean room is a critical link in the semiconductor production process, which directly affects the quality and production efficiency of products. Hejie Technology Electronic Clean Engineering Company will delve into the construction and maintenance costs of a Class 10000 semiconductor cleanroom, aiming to provide valuable reference and inspiration for related enterprises.The construction of a semiconductor purification workshop is a complex and intricate process, and its cost covers multiple aspects of expenses. In order to help enterprises better understand and plan the construction budget of purification workshops, MFMIC this article will analyze in detail the main components of the construction cost of semiconductor purification workshops.

1、the construction cost of a Class 10000 semiconductor cleanroom is a complex and massive system, mainly including design costs, material costs, equipment costs, and construction costs.

Design costs are a part of construction costs, typically determined by the complexity of the design scheme and the qualifications of the design company. A design scheme that meets the standards of a Class 10000 semiconductor cleanroom needs to fully consider factors such as the layout of the workshop, the configuration of the air purification system, and temperature and humidity control. The design team needs to have rich experience and professional knowledge to ensure the scientific and practical nature of the design scheme. Therefore, although the design cost does not account for a high proportion of the entire construction cost, its importance cannot be ignored.

Material costs are an important component of construction costs. A large-scale semiconductor cleanroom requires the use of special materials such as purification wall panels, floors, ceilings, filters, etc. These materials need to have good sealing, corrosion resistance, and ease of cleaning to ensure the cleanliness and stability of the workshop. The prices of these special materials are usually high, which has a significant impact on costs. Therefore, when selecting materials, it is necessary to comprehensively consider factors such as material performance, price, and supplier reputation.

Equipment costs are the majority of construction costs. A Class 10000 semiconductor cleanroom needs to be equipped with various purification and control equipment, such as air conditioning systems, air purification equipment, pressure control equipment, etc. These devices need to have characteristics such as high efficiency, stability, and easy maintenance to ensure the normal operation of the workshop and product quality. These devices are expensive, and there is a significant price difference between devices of different brands and models. Therefore, when selecting equipment, it is necessary to fully consider factors such as equipment performance, price, after-sales service, and maintenance costs.

Construction costs are another important component of construction costs. The construction of a Class 10000 semiconductor cleanroom requires professional construction, equipment installation, electrical engineering, etc. The construction process requires strict adherence to relevant specifications and standards to ensure the cleanliness and stability of the workshop. The construction team needs to have rich experience and professional knowledge to ensure construction quality and progress. Therefore, construction costs usually account for a large proportion of the entire construction cost.

2、Design and planning costs

Design and planning are the starting point for the construction of semiconductor purification workshops, and also the key to ensuring the smooth progress of subsequent construction. The cost of this stage mainly includes consulting service fees for the cleanroom design team, design scheme development fees, drawing fees, etc. The design content includes workshop layout planning, airflow organization design, temperature and humidity control scheme, as well as anti-static and intelligent system design. The level of design cost depends on the size and complexity of the workshop, as well as the professional level of the design team, usually accounting for 5% -10% of the total cost.

3、Cost of building materials

The semiconductor purification workshop has extremely high requirements for building materials, which need to meet characteristics such as dust prevention, anti-static, and corrosion resistance. Common building materials include wall materials (such as color steel plates, stainless steel plates, glass, etc.), floor materials (such as epoxy resin floors, PVC floors, etc.), and ceiling materials (such as aluminum alloy ceilings, color steel plate ceilings, etc.). The cost of these materials depends on the brand, quality, and usage, and the overall cost of building materials is usually between 500-1200 yuan per square meter.

4、Purification equipment cost

Purification equipment is the core part of semiconductor purification workshops, mainly including high-efficiency particulate air (HEPA) filters, air shower rooms, transfer windows, etc. These devices are used to filter particles in the air, control the entry and exit of dust by personnel, and maintain cleanliness during material transfer. The cost of purification equipment depends on the size of the workshop and the number of equipment, usually requiring an investment of 500-1500 yuan per square meter.

5、Air conditioning and ventilation system costs

The semiconductor purification workshop has extremely high requirements for temperature, humidity, and air cleanliness, thus requiring the installation of efficient air conditioning and ventilation systems. These systems include air conditioning units, fan filtration units (FFUs), ducts and pipes, etc. The cost of air conditioning and ventilation systems is usually between 800-2000 yuan per square meter, depending on the system size, brand, and configuration requirements.

6、Anti static and intelligent system costs

Semiconductor production is very sensitive to static electricity, so the purification workshop needs to be equipped with anti-static systems, including anti-static floors, ion fans, etc. At the same time, in order to monitor cleanliness, temperature and humidity parameters in real time, an intelligent monitoring system needs to be installed. The cost of anti-static and intelligent systems is usually between 300-800 yuan per square meter.

7、Construction and installation costs

The construction and installation costs include the installation of walls, floors, and ceilings, the installation and commissioning of purification equipment, as well as the installation of air conditioning and ventilation systems. These costs depend on the difficulty of construction, the duration, and the professional level of the construction team. The construction cost is usually between 300-800 yuan per square meter.

8、Acceptance and maintenance costs

After the completion of the semiconductor purification workshop, acceptance is required, and the acceptance cost includes cleanliness testing, equipment performance testing, etc. In addition, the daily maintenance of the workshop also requires certain expenses, including equipment maintenance, filter replacement, etc. The cost of acceptance and maintenance usually accounts for a small proportion of the total cost, but it cannot be ignored.

9、Other expenses

In addition to the main costs mentioned above, the construction of semiconductor purification workshops may also involve some other expenses, such as the installation costs of power supply systems, lighting systems, water supply and drainage systems, as well as the purchase costs of special process equipment (such as UV curing equipment). These costs depend on specific needs and configurations.

Through scientific and reasonable planning and strict cost control measures, enterprises can ensure that the construction quality of semiconductor purification workshops meets production needs and lay a solid foundation for future development and expansion.

MFMIC In short that the construction and maintenance costs of semiconductor cleanrooms are an important issue that requires high attention and concern from enterprises. By comprehensively considering multiple factors and developing specific construction and maintenance plans, enterprises can effectively reduce construction and maintenance costs, improve workshop operational efficiency and product quality. At the same time, enterprises also need to continuously strengthen technological innovation and cooperation to adapt to the constantly changing market demands and competitive environment.

Media Contact

Company Name: MFMIC Technology Company Limited

Email: Send Email

Phone: 83741556

Address:Rm 602, 6/F, Wayson Comm Bldg, 28 Connaught West

Country: HongKong

Website: https://mfmic.com.hk/